| What Armada’s Diversity, Equity and Inclusion Commitment Means to You – Click Here |

Armada creates innovative, fully integrated supply chain solutions that deliver competitive advantages and improve business performance for our clients.

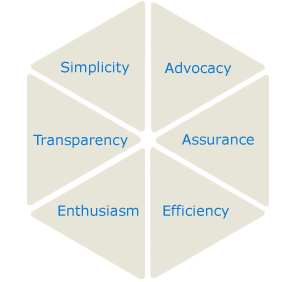

We believe that there’s a better way to run global supply chains. A better way rooted in simplicity, transparency and extraordinary service to our clients.

We are changing the way supply chains are managed—now and for the future—through innovation and collaboration with our clients.

We provide logistic solutions that create smaller, smarter and more agile supply chains that adjust to our clients' evolving marketplace demands.

The Armada Advantage

Armada Wins EPA's 2020 SmartWay Excellence Award